Case History: Huihuang United Food sceglie il sistema integrato ECOBLOC® ERGON di SMI

Case History: Huihuang United Food sceglie il sistema integrato ECOBLOC® ERGON di SMI

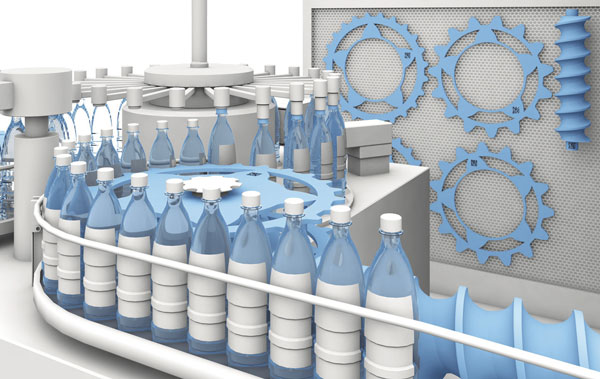

Il consumo di acqua confezionata è in costante crescita in ogni parte del mondo e le previsioni dei maggiori istituti di ricerca indicato che la tendenza continuerà anche in futuro; non fa eccezione la Cina, dove, nel solo primo trimestre 2023, si è registrato un incremento nelle vendite di acqua in bottiglia pari al 10,9% (Fonte Globaldata). Di fronte ad uno scenario di forte espansione, i principali marchi cinesi del settore beverage si sono lanciati in un programma di investimenti in linee di produzione più moderne ed efficienti; ne è un esempio quanto successo nella città di Tianjing, dove l’azienda Huihuang United Food, importante imbottigliatore di marchi leader come Coca-Cola e C’estbon, si è rivolta a SMI, con cui collabora da anni, per la fornitura di un sistema integrato di soffiaggio-riempimento-tappatura ECOBLOC® ERGON, il primo installato da SMI in Cina, destinato all’imbottigliamento di prodotti a marchio C’estbon in contenitori PET da 4,5 L.

Huihuang United (Tianjin) Food Co. Ltd.

Huihuang United (Tianjin) Food Company viene fondata nel 2011 come filiale di Macau Huiyang International Investiment Co. Ltd., società appartenente al colosso industriale Zhuhai Zhongfu Enterprises Co. L’azienda di Tianjin, che attualmente dà lavoro a circa 300 persone, sin dall’inizio della sua attività si è contraddistinta per la capacità di gestire produzioni di grandi dimensioni per conto terzi; dal 2011 collabora, a esempio, con la multinazionale statunitense Coca-Cola. Risale allo stesso anno la prima fornitura di SMI a Huihuang United (Tianjin) Food Company con l’installazione di una fardellatrice SK 802 F per il confezionamento in fardelli solo film di bottiglie PET da 0,55 L nei formati 6×4, 5×3 e 4×3: tale macchina è attualmente installata in una delle due linee di produzione da 48.000 bottiglie/ora dello stabilimento di Tianjin. L’insediamento dell’azienda cinese si estende su una superficie di circa 100.000 mq, di cui 68.000 mq occupati dagli impianti di imbottigliamento. La sola area di magazzino occupa una superficie di 36.000 mq e permette a Huihuang United (Tianjin) Food Co. di tenere in deposito più di 1,5 milioni di confezioni di acqua a marchio C’estbon, assicurando nel contempo ai propri clienti una consegna giornaliera di 250.000 pacchi.

All’interno dell’area adibita alla produzione sono attualmente installate 6 linee complete per l’imbottigliamento e il confezionamento di vari prodotti in svariati formati di pacco. Il nuovo sistema integrato ECOBLOC® ERGON recentemente fornito da SMI si inserisce all’interno di una linea di produzione da 6.000 bottiglie/ora per contenitori PET da 4,5 e 6 L a marchio C’estbon; il nuovo impianto si aggiunge quindi alla prima stiro-soffiatrice fornita da SMI nel 2015 (in partnership con Sacmi), destinata alla produzione della medesima bottiglia.

La fardellatrice SK 600 F fornita nel 2013, dedicata al confezionamento in solo film delle bottiglie PET da 0,35 e 0,55 L, risulta invece installata all’interno della linea da 36.000 bph.

Una chiacchierata con il cliente

Intervista a Huang Gang, Plant Manager di Huihuang United (Tianjin) Food Co. Ltd.

D: Quando e come è iniziata l’attività produttiva di Huihuang United (Tianjin) Food Co.?

R: La nostra azienda ha avviato l’attività imbottigliamento di bevande nel 2011 e si è subito contraddistinta sin dall’inizio grazie alla produzione di bevande a marchio Coca-Cola e C’estbon.

D: Quali sono state le principali tappe della crescita aziendale?

R: Il primo investimento risale all’anno 2011, anno di costituzione della società Huijuang United Food, nell’ambito della collaborazione con Coca-Cola per il processo di imbottigliamento e confezionamento delle loro bevande. Un altro passo avanti è stato fatto nel 2013, quando la capacità produttiva dei nostri impianti è stata potenziata per far fronte alla nuova collaborazione con il marchio C’estbon. Oggi, a distanza di 10 anni, l’innovazione continua ci ha portato a realizzare un nuovo progetto per incrementare ulteriormente la nostra produzione grazie al nuovo sistema integrato ECOBLOC® ERGON fornito da SMI.

D: Quali sono i principali fattori che vi hanno convinto ad investire in una nuova linea di imbottigliamento fornita da SMI?

R: Nel 2015 abbiamo acquistato una riempitrice e una stiro-soffiatrice rotativa SMI per la produzione di contenitori PET da 4,5 L, che ci ha soddisfatto e ci ha garantito negli anni una produzione stabile e di successo. Per questa ragione, anche per il recente investimento che si è reso necessario per incrementare la produzione in risposta ad un forte domanda del mercato, non abbiamo avuto dubbi a scegliere SMI e ad acquistare un nuovo sistema integrato ECOBLOC® ERGON per la produzione di contenitori PET di grande capacità da 4,5 e 6 L destinati all’imbottigliamento di acqua piatta.

D: Come vede il mercato del settore food & beverages in futuro?

R: Ritengo che in questo settore ci siano in Cina molti margini di sviluppo e innovazione, considerata la costante crescita del benessere sociale di fasce sempre più ampie della popolazione e il miglioramento dello stile di vita delle persone. Le aziende che operano nel settore degli alimentari e delle bevande devono prestare sempre maggiore attenzione alle nuove esigenze dei consumatori, creando un’offerta ampia e diversificata di prodotti realizzati con processi avanzati e sostenibili per il benessere del pianeta.

D: Come differiscono i prodotti di Huihuang United (Tianjin) Food Co. dagli altri disponibili sul mercato?

R: La qualità e la sicurezza rappresentano i principi fondamentali alla base della nostra attività aziendale. Dal mio punto di vista sono proprio questi gli elementi che ci differenziano maggiormente e ci permettono di avere successo sul mercato.

D: Quanto è importante per Huihuang United (Tianjin) Food Co. la presenza diretta di SMI in Cina tramite la filiale SMI Machinery Beijing?

R: È fondamentale per garantirci un supporto tecnico e di post-vendita rapido, efficiente e conveniente. La presenza di una filiale locale ha rappresentato e rappresenterà sempre di più in futuro un elemento essenziale per la nostra collaborazione con SMI, perché una grande azienda come la nostra deve poter contare in ogni momento su un supporto qualificato e di alto livello da parte dei propri fornitori di fiducia.

Soluzioni SMI per Huihuang United (Tianjin) Food Co.

La collaborazione tra Huihuang United (Tianjin) Food Co e SMI è iniziata 12 anni fa con l’acquisto di una fardellatrice in film termoretraibile SK 802 F, installata all’interno della linea di produzione dedicata al confezionamento delle bottiglie a marchio Coca-Cola da 0,5 L nei formati 6×4, 5×3 e 4×3 solo film e con la successiva fornitura di una fardellatrice SK 600 F installata sulla linea da 36.000 bottiglie/ora, necessaria per incrementare la produzione delle bottiglie da 0,35 e 0,55 L.

Nell’ambito dell’imballaggio primario la collaborazione tra l’azienda cinese e SMI è iniziata nel 2015, con l’installazione di una stiro-soffiatrice a 6 cavità per la produzione di contenitori PET da 4,5 le e 6 L destinati al marchio C’estbon. Il recente investimento nel primo impianto ECOBLOC® ERGON di SMI in Cina ha permesso al cliente di incrementare la produzione dei formati 4,5 e 6 L, molto richiesti dal mercato e di accrescere ulteriormente il profilo qualitativo e tecnologico delle soluzioni adottate.

Nell’ambito dell’imballaggio primario la collaborazione tra l’azienda cinese e SMI è iniziata nel 2015, con l’installazione di una stiro-soffiatrice a 6 cavità per la produzione di contenitori PET da 4,5 le e 6 L destinati al marchio C’estbon. Il recente investimento nel primo impianto ECOBLOC® ERGON di SMI in Cina ha permesso al cliente di incrementare la produzione dei formati 4,5 e 6 L, molto richiesti dal mercato e di accrescere ulteriormente il profilo qualitativo e tecnologico delle soluzioni adottate.

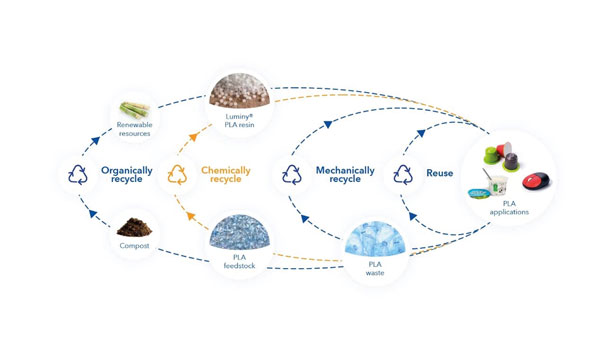

Huihuang United (Tianjin) Food e Zhuai Zhongfu sono due realtà industriali particolarmente attente all’ambiente; conseguentemente il risparmio energetico e la riduzione delle emissioni di anidride carbonica sono diventati uno dei pilastri della responsabilità sociale d’impresa, che richiede l’impiego sempre più massiccio di nuove attrezzature e tecnologie pensate per combinare efficienza aziendale e tutela dell’ecosistema.

Impianto di stiro-soffiaggio/riempimento/tappatura ECOBLOC® ERGON 6-16-4 HC HEVF

Bottiglie lavorate: contenitori PET da 4,5 e 6 L di acqua naturale C’estbon.

Vantaggi principali:

• Soluzione compatta per lo stiro-soffiaggio, il riempimento e la tappatura di bottiglie PET di grande capacità

• Non richiede la sciacquatrice e i nastri ad aria tra la soffiatrice e la riempitrice

• Processo di riempimento e tappatura preciso e veloce, grazie al sistema di controllo elettronico delle operazioni, alle aste di stiro motorizzate e all’impiego di valvole ad alta efficienza comandate da flussimetri

• Ridotti consumi energetici

• Lampade per il riscaldamento preforme a raggi IR ad alta efficienza energetica

• Sistema di recupero d’aria a doppio stadio, che consente di ridurre i costi energetici per la produzione di aria compressa ad alta pressione

• Valvole di riempimento che gestiscono due velocità al fine di riempire in modo omogeneo, efficiente e senza fuoriuscite di prodotto dal contenitore. La durata dei cicli di riempimento (lento o veloce) è gestibile in modo semplice e intuitivo tramite le ricette presenti nell’interfaccia uomo-macchina (HMI Posyc®)

• Ridotti costi di manutenzione e di gestione dell’impianto

Orientatore tappi EASY-CAP

Funzioni: orientatore tappi gravitazionale, che preleva i tappi da una tramoggia e li orienta correttamente fino a portarli alla linea di imbottigliamento.

Vantaggi principali:

• Struttura molto compatta, realizzata in acciaio AISI 304, adatta a qualsiasi soluzione di layout

• Funzionamento fluido e lineare, per trasportare solo i tappi orientati correttamente

• Sistema adatto a diversi tipi di tappi in plastica

• Interfaccia operatore user-friendly, che consente un facile ed efficiente utilizzo della macchina da parte dell’operatore.

A scenario of strong expansion and investments

Case History: Huihuang United Food chose the integrated system ECOBLOC® ERGON by SMI

The consumption of bottled water is constantly growing in every part of the world and the forecasts of the major research institutes indicated that the trend will continue in the future. China is no exception, where, in the first quarter of 2023 alone, there was an increase in sales of bottled water of 10.9% (Source Globaldata). Faced with a scenario of strong expansion, the main Chinese brands in the beverage sector have launched a program of investments in more modern and efficient production lines, an example is what happened in the city of Tianjing, where the company Huihuang United Food, an important bottler of leading brands such as Coca-Cola and C’estbon, turned to SMI, with which it has been collaborating for years, for the supply of an integrated blowing-filling-capping system ECOBLOC® ERGON, the first installed by SMI in China, intended for bottling C’estbon brand products in 4.5 L PET containers.

Huihuang United (Tianjin) Food Co. Ltd.

Huihuang United (Tianjin) Food Company was founded in 2011 as a subsidiary of Macau Huiyang International Investment Co. Ltd., a company belonging to the industrial giant Zhuhai Zhongfu Enterprises Co. The Tianjin-based company, which currently employs about 300 people, has distinguished itself since the beginning of its activity for the ability to manage large productions for third parties; since 2011 it collaborates, for example, with the US multinational Coca-Cola. The first supply of SMI to Huihuang United (Tianjin) Food Company dates back to the same year, with the installation of an SK 802 F shrinkwrapper for packing 0.55 L PET bottles in 6×4, 5×3 and 4×3: this machine is currently installed in one of the two 48,000 bottles/hour production lines of the Tianjin plant. The Chinese company extends over an area of about 100,000 square meters, of which 68,000 square meters occupied by bottling plants. The warehouse area alone occupies an area of 36,000 square meters and allows Huihuang United (Tianjin) Food Co. to store more than 1.5 million packs of C’estbon-branded water, while ensuring its customers a daily delivery of 250,000 packs.

Within the production area, 6 complete lines are currently installed for bottling and packaging various products in various pack formats. The new ECOBLOC® ERGON integrated system recently supplied by SMI, is part of a 6,000 bottles/hour production line for 4.5 and 6 L PET containers branded C’estbon; the new plant is therefore added to the first stretch-blow moulder supplied by SMI in 2015 (in partnership with Sacmi), intended for the production of the same bottle.

While the SK 600 F shrinkwrapper supplied in 2013, dedicated to the packaging of 0.35 and 0.55 L PET bottles in film-only, is installed inside the 36,000 bph line.

A chat with the customer

Interview with Huang Gang, Plant Manager of Huihuang United (Tianjin) Food Co. Ltd.

Q: When and how did Huihuang United (Tianjin) Food Co. start production?

A: Our company started the beverage bottling business in 2011 and immediately distinguished itself thanks to the production of Coca-Cola and C’estbon drinks.

Q: What were the main stages of the company’s growth?

A: The first investment dates back to 2011, the year Huijuang United Food was established, as part of the collaboration with Coca-Cola for the bottling and packaging process of their beverages. Another step forward was made in 2013, when the production capacity of our plants was enhanced to cope with the new collaboration with the C’estbon brand. Today, after 10 years, continuous innovation has led us to create a new project to further increase our production thanks to the new integrated system ECOBLOC® ERGON supplied by SMI.

Q: What are the main factors that convinced you to invest in a new bottling line supplied by SMI?

A: In 2015 we purchased an SMI rotary stretch-blow moulder and filler for the production of 4.5 L PET containers, which satisfied us and has guaranteed stable and successful production over the years. For this reason, also due to the recent investment that was necessary to increase production in response to a strong market demand, we had no doubts when choosing SMI for a new ECOBLOC® ERGON integrated system for the production of large capacity PET containers of 4.5 and 6 L for bottling still water.

Q: How do you see the food & beverages market in the future?

A: I believe that in this sector there is a lot of room for development and innovation in China, given the constant growth of social well-being of increasingly large sections of the population and the improvement to people’s lifestyle. Companies operating in the food and beverage sector must pay more and more attention to the new needs of consumers, creating a wide and diversified offer of products made with advanced and sustainable processes for the well-being of the planet.

Q: How do Huihuang United (Tianjin) Food Co. products differ from others available on the market?

A: Quality and safety are the fundamental principles underlying our business activity. From my point of view, these are the elements that differentiate us the most and allow us to succeed within the market.

Q: When is it important for Huihuang United (Tianjin) Food Co. to have SMI’s direct presence in China through its subsidiary SMI Machinery Beijing?

A: It is essential to guarantee a fast, efficient and convenient technical and after-sales support.

The presence of a local branch has represented and will increasingly represent in the future, an essential element for our collaboration with SMI, because a large company like ours, must be able to count on qualified and high-level support from its trusted suppliers at all times.

SMI solutions for Huihuang United (Tianjin) Food Co.

The collaboration between Huihuang United (Tianjin) Food Co and SMI began 12 years ago with the purchase of an SK 802 F shrinkwrapper, installed within the production line dedicated to the packing of 0.5 L Coca-Cola bottles in 6×4, 5×3 and 4×3 in film only and with the subsequent supply of an SK 600 F shrinkwrapper installed on the 36,000 bottles/hour line, necessary to increase the production of 0.35 and 0.55 L bottles.

In the field of primary packaging, the collaboration between the Chinese company and SMI began in 2015, with the installation of a 6-cavity stretch-blow moulder for the production of 4.5 and 6 L PET containers for the C’estbon brand. The recent investment in SMI’s first ECOBLOC® ERGON plant in China, has allowed the customer to increase the production of 4.5 and 6 L formats, which are in high demand by the market, and to further increase the quality and technological profile of the solutions adopted.

Huihuang United (Tianjin) Food and Zhuai Zhongfu are two industrial companies particularly attentive to the environment. Consequently, energy saving and the reduction of carbon dioxide emissions have become one of the pillars of corporate social responsibility, which requires the increasingly massive use of new equipment and technologies designed to combine business efficiency and ecosystem protection.

ECOBLOC® ERGON 6-16-4 HC HEVF STRETCH-BLOWING/FILLING/CAPPING SYSTEM

Containers worked: 4.5 and 6L PET containers of C’estbon natural water.

Main advantages:

• Compact solution for stretch-blow moulding, filling and capping large capacity PET bottles

• Does not require a rinsing machine and air belts between blower and filler

• Precise and fast filling and capping process, thanks to the electronic control system of operations, motorised stretch rods and the use of high-efficiency valves controlled by flow meters

• Reduced energy consumption

• Energy-efficient IR preform heating lamps

• Two-stage air recovery system, which reduces energy costs for high-pressure compressed air production

• Filling valves that manage two speeds in order to fill homogeneously, efficiently and without product spilling from the container. The duration of the filling cycles (slow or fast) can be managed in a simple and intuitive way through the recipes in the human-machine interface (HMI Posyc®)

• Reduced maintenance and management costs of the plant.

EASY-CAP elevator/sorter

Function: Gravitational cap sorter, which takes the caps from a hopper and turns them correctly until they reach the bottling line.

Main advantages:

• Very compact structure, made of AISI 304 steel, suitable for any layout solution

• Smooth and linear operation, that will only carry the caps that are in the correct position

• System suitable for different types of plastic caps

• User-friendly operator interface, which allows easy and efficient use of the machine by the operator.

Evento internazionale leader di settore, IVS è un vero information hub a cui non puoi mancare

Evento internazionale leader di settore, IVS è un vero information hub a cui non puoi mancare