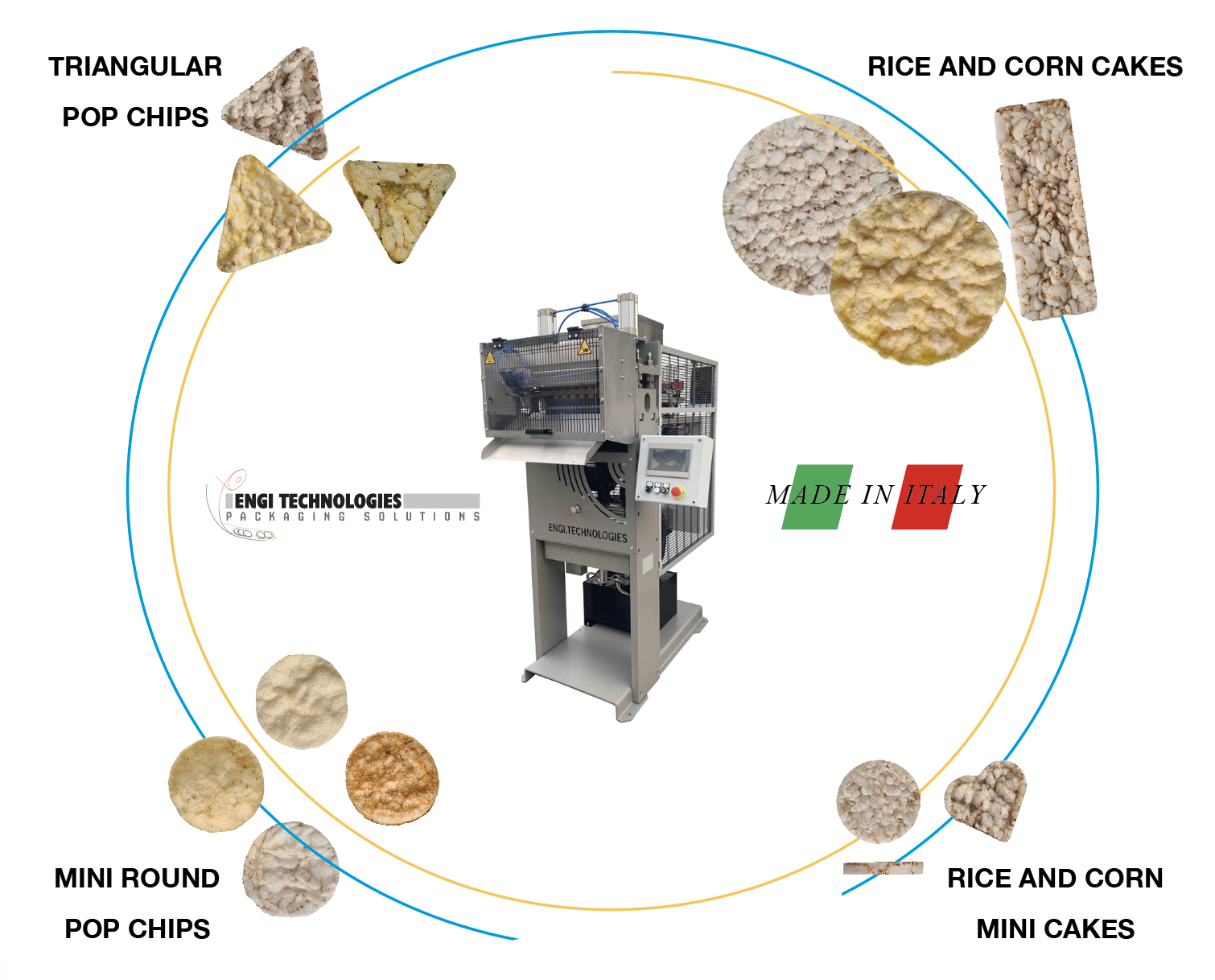

ENGI TECHNOLOGIES focuses its design and constructive expertise on the production of machines and plants for rice-cake, mini rice-cake, and non-fried snack machines, combining with salt flavouring and chocolate coating lines.

ENGI TECHNOLOGIES focuses its design and constructive expertise on the production of machines and plants for rice-cake, mini rice-cake, and non-fried snack machines, combining with salt flavouring and chocolate coating lines.

ENGI TECHNOLOGIES – headquartered in Turin – boasts fully Made in Italy technology and quality safety combining with a technical department with more than 40 years’ experience, which has been able to create a comprehensive range of machinery to work any kind of cereal, and cereal with legumes or micropellets.

For rice-cake production, the company offers 2 different lines of machines working on hydraulic principle:

– ONE CAKE and DOUBLE CAKE, for small outputs, workshops, and mills,

– XP-CAKE 6, for industrial production and constant quality.

For snacks production, the company offers 2 different models of machines, such as:

– HYDRO-SNACKS, working on hydraulic principle for industrial production,

– SNACK-TRON, fully electric machine for industrial production.

All machines are equipped with Siemens PLC, remote technical assistance, titanium nitride moulded, and pneumatic raw material feeding system for zero waste.

Application systems and machinery personalization

All machines can be equipped with systems that can increase hourly production (avoiding further maintenance), reduce pneumatic or hydraulic noise, zero raw material waste, as well as automatic lubrication systems for mechanic parts and much more.

The most sold equipment is:

Application MP: Mechanic technology to guarantee mould axiality and to produce identical snack and rice cakes at every cycle.

Application MP-EC: Technology that includes the application MP and enables mould opening of 200 mm for easy cleaning.

ENGI TECHNOLOGIES, supplier high-automation plants

The company can design and supply lines and plants upon customer’s specific requirements, featuring a high level of automation.

ENGI TECHNOLOGIES provides mixing systems and raw material automatic feeding systems; conveyor belts that vary their speed to the machinery’s work cycle; snack and rice-cake salting and flavouring lines, and chocolate coating lines with cooling tunnel.